How Do Linear Motors Work? The Complete Guide for Engineers and Innovators

Linear motors are reshaping the future of automation by delivering direct, ultra-precise linear motion without relying on mechanical transmission elements like screws, belts, or gears. Industries ranging from semiconductors to digital printing demand accuracy, speed, and clean motion — and linear motors deliver.

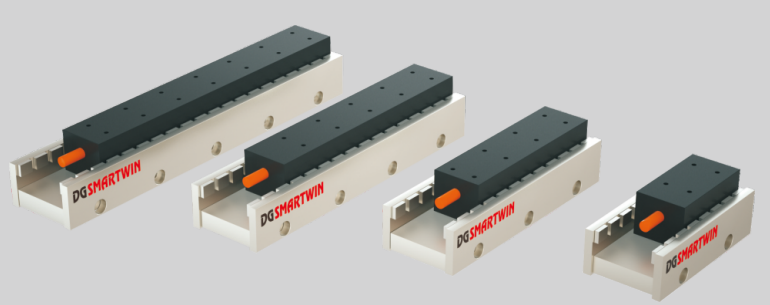

Smartwin's advanced iron core, bilateral iron core, and coreless linear motors are engineered for applications where high-precision and clean operation are critical. In this complete guide, you'll learn how linear motors work, the different types, how to integrate them, and how to choose the right one for your needs.

What Is a Linear Motor?

A linear motor is an electric motor designed to produce straight-line motion rather than rotation. Imagine unrolling a traditional rotary motor into a flat structure — that's the essence of a linear motor. It transforms electrical energy directly into linear mechanical motion.

Why Linear Motors?

Eliminate mechanical conversion components

Higher precision and control

Faster acceleration

Minimal wear and reduced maintenance

Smartwin's linear motors are especially suited for semiconductor, laser, lithium battery, LCD panel, and photovoltaic production — all of which demand ultra-clean, high-speed motion.

How Does Linear Motor Work?

Linear motors rely on electromagnetic interaction between the forcer (primary) and the magnet track (secondary). When electric current flows through the motor coil, it creates a magnetic field. This field interacts with the permanent magnets in the track, generating a Lorentz force that propels the mover along a straight path.

Main Components:

Forcer (Primary): Contains electromagnetic coils that generate the driving force.

Magnet Track (Secondary): Contains permanent magnets, either stationary or mobile.

Feedback Device (e.g., Encoder): Provides real-time position feedback.

Smartwin's linear motors are designed with stable analog current control, allowing for more refined force control, especially important in delicate precision handling.

Types of Linear Motors

We offers three core categories of linear motors. Here's how they differ:

1. Iron Core Linear Motor

Description: Includes laminated steel cores inside the coil.

Advantages: High force density, ideal for heavy load applications.

Use Cases: LCD panel handling, solar panel module movement, etc.

Note: Slight cogging may occur, but new materials help minimize this.

2. Bilateral Iron Core Linear Motor

Description: Coil is positioned between two magnet tracks for balanced force.

Advantages: Even greater thrust, compact footprint, excellent thermal stability.

Use Cases: Semiconductor production, CNC machinery, and more.

3. Coreless (Ironless) Linear Motor

Description: Coil suspended between magnet arrays without a steel core.

Advantages: No cogging, no magnetic attraction, ultra-smooth motion.

Use Cases: High-precision inspection, digital printing, 3C device assembly.

The three different types of linear motors feature:

Fast speed with high precision

Micron-level speed fluctuation

Clean, dust-free, and noise-free operation

Performance Characteristics

Comparison of linear motors types from Smartwin are engineered for performance in high-demand environments.

| Feature | Benefit |

|---|---|

| Micron-level Speed Fluctuation | Ensures smooth, accurate motion |

| Analog Current Control | Enables advanced force control |

| Compact Size, Large Thrust | Space-saving without sacrificing performance |

| Dust-Free, Noise-Free | Perfect for cleanroom and quiet environments |

How Linear Motors Compare to Ball Screws

| Feature | Linear Motor | Ball Screw |

|---|---|---|

| Speed | Up to 5 m/s+ | Up to 1.5 m/s |

| Positioning Accuracy | ±1 μm or better | ±10–100 μm |

| Backlash | None | Present |

| Noise | Silent | Noisy at high speeds |

| Maintenance | Low | Requires lubrication |

| Cleanroom Suitability | Excellent | Poor |

Applications of Linear Motors

Smartwin's linear motors are purpose-built for high-tech industries:

Semiconductor Industry

Wafer stage systems

Photolithography platforms

Chip packaging lines

Laser Industry

Laser cutting and engraving

Optical positioning stages

Lithium Battery Production

Battery module assembly

Precision electrode coating

LCD & Solar Panel Industry

Glass substrate transport

Precise layer alignment and coating

3C Electronics Assembly

Smartphone and tablet automation

High-speed pick-and-place

Digital Printing

Printhead scanning

Ultra-fast, accurate print stages

Explore: [Top 5 Applications for Smartwin's Ironless Linear Motors]

Integrating Linear Motors with Servo Drives and Encoders

For effective operation, linear motors must be integrated with:

1. Servo Drives

Convert control signals into power for the motor

Enable advanced features like torque control and auto-tuning

2. Encoders

Provide feedback on position and velocity

Zhiying's SMARTWIN CH22405A encoder ensures ultra-precise control

3. Motion Controller

Coordinates multi-axis systems

Synchronizes motor operations with feedback for high-speed control

Integration Checklist:

Select compatible servo drives (supporting analog current control)

Use high-resolution encoders for sub-micron feedback

Optimize thermal management (especially for high-duty cycles)

Choosing the Right Linear Motor

Here's how to evaluate your needs:

| Criteria | Recommendation |

|---|---|

| Precision Requirement | Coreless motors for best results |

| Force Demand | Iron core or bilateral iron core motors |

| Stroke Length | Match to application travel range |

| Speed | All series offer fast acceleration |

| Environment | Coreless preferred for cleanrooms |

| Mounting Space | Use compact designs where space is tight |

Need help? Contact Smartwin's engineers for system matching and integration support.

Maintenance Tips to Maximize Lifespan

Linear motors are inherently low-maintenance. Still, for optimal operation:

Keep the magnet track clean — dust and metal debris can degrade performance

Monitor motor temperature — avoid overheating through thermal sensors

Check encoder alignment — to maintain feedback accuracy

Use diagnostics tools — servo drives offer built-in health monitoring

Read More: [Linear Motor Maintenance: Tips to Maximize Lifespan & Precision]

Conclusion

Linear motors offer unmatched precision, speed, and reliability for modern high-tech manufacturing. Whether you need high thrust in a compact footprint or cog-free motion for cleanroom production, Smartwin's product lines cover it all — from iron core to bilateral to coreless linear motors.

By understanding how linear motors work and their application potential, you can design and implement motion systems that outperform traditional drive methods in accuracy, cleanliness, and longevity.

Need a custom solution? Explore Zhiying Linear Motors now

FAQs

Q1: Which industries are best suited for coreless linear motors?

A: Semiconductor, precision inspection, digital printing, and 3C assembly.

Q2: How is the thrust performance of Smartwin's motors?

A: Using new materials and optimized coil structure, they deliver high thrust in a compact volume.

Q3: Can I use Smartwin linear motors in cleanroom environments?

A: Absolutely. With zero particle generation and silent operation, they are ideal for ISO Class 5–7 cleanrooms.

Q4: Does Smartwin support customization?

A: Yes. we offers OEM and ODM development to fit your exact application and system.

En

En