Linear motors are essential components in high-performance machinery across industries like semiconductors, automation, printing, and medical equipment. While their direct-drive, contactless nature makes them inherently low-maintenance, proactive care and condition monitoring are vital to ensure their long-term reliability, precision, and cost-efficiency.

In this guide, we explore best practices and practical tips to maintain Zhiying's linear motors — both iron-core and ironless — to maximize operational lifespan and preserve motion accuracy.

Why Maintenance Matters for Linear Motors

Despite having no mechanical contact or wear surfaces like belts, screws, or gears, linear motors are still exposed to:

Thermal cycling and heat buildup

Environmental contamination (dust, oil, or metal shavings)

Magnetic particle accumulation

Misalignment from mechanical stress or load changes

If not addressed, these issues can result in:

Reduced positioning accuracy

Decreased force output

Thermal derating or failure

Costly unplanned downtime

Step 1. Keep It Clean: Managing Contamination

Ironless Motors

Zhiying's ironless linear motors are often used in cleanrooms and labs, but even small particles can affect precision.

Tip:

Use clean, filtered air for environmental enclosures

Periodically clean the platen using lint-free cloths and isopropyl alcohol

Avoid ferrous particles near magnetic tracks

Iron-Core Motors

Iron-core motors are more rugged but can accumulate particles around the magnet array.

Tip:

Clean motor surfaces regularly to prevent buildup

Use protective covers or bellows in dusty environments

Step 2. Monitor and Manage Temperature

Linear motors generate heat during operation. Excess heat can reduce magnetic strength and degrade insulation.

Best Practices:

Monitor motor temperatures using built-in or external sensors

Use Zhiying's water-cooling options for high-duty-cycle applications

Ensure heat sinks and mounting plates are properly thermally coupled

Warning Sign:

If the motor feels hot to touch or performance degrades during long cycles, thermal saturation may be occurring.

Step 3. Check for Mechanical Alignment

Linear motors rely on accurate rail alignment and mounting flatness. Over time, mechanical components may shift due to vibration, impact, or thermal expansion.

Inspection Routine:

Verify the parallelism between the forcer and platen

Check for uneven wear on guide rails or bearing blocks

Ensure consistent air gap (especially for ironless models)

Impact of Misalignment:

Increased friction

Magnetic imbalance

Reduced motor life and performance degradation

Step 4. Inspect Cabling and Connectors

Worn or loose connections can interrupt current flow, introduce noise, or reduce motor responsiveness.

Tips:

Rout cables with strain relief and avoid sharp bends

Inspect power and encoder connectors for corrosion or wear

Replace damaged cables immediately

Zhiying Advantage:

Motors can be equipped with robust industrial-grade connectors for better reliability.

Step 5. Encoder Health Check

Most Zhiying linear motors are paired with high-resolution encoders. Encoder issues can cause position drift, jitter, or loss of feedback.

Maintenance Tips:

Clean encoder scales and reader heads gently

Calibrate encoders after system maintenance or shock

Check for cable shielding to prevent electrical noise

Encoder Type Compatibility:

Optical and magnetic encoders have different cleaning needs

Review OEM specs for cleaning solvents and access protocols

Step 6. Lubricate Guideways (If Applicable)

While the motor itself does not require lubrication, linear guides, bearings, or ball slides may.

Suggestions:

Use OEM-approved lubricants

Follow schedules based on operating hours and load cycles

Avoid over-lubrication, which can attract dust

Step 7. Schedule Preventive Maintenance

Create a calendar-based or usage-based preventive maintenance plan.

Checklist Includes:

Visual inspection (monthly)

Air gap verification (quarterly)

Cleaning and thermal check (bi-annually)

Full system calibration (annually)

Documentation Tip:

Maintain service logs to identify recurring issues and track performance degradation over time.

Step 8. Use OEM Tools and Support

Zhiying provides a range of technical resources and engineering support:

Installation manuals and CAD drawings

Thermal simulation models

Recommended cleaning agents and tools

Encoder calibration software (on request)

Pro Tip:

If your application involves high precision or continuous 24/7 operation, consider a condition monitoring system or regular service agreement with Zhiying technical support.

Conclusion

Linear motors are among the most reliable motion systems available, but proactive care ensures peak performance and extended lifetime. With simple maintenance routines and proper environmental controls, users can preserve the precision, speed, and value of their Zhiying motors for years.

Investing in maintenance isn't just about preventing failure—it's about preserving accuracy and protecting your investment.

Need support or replacement parts? Visit zhiyingmotor.com or contact our technical service team to learn more.

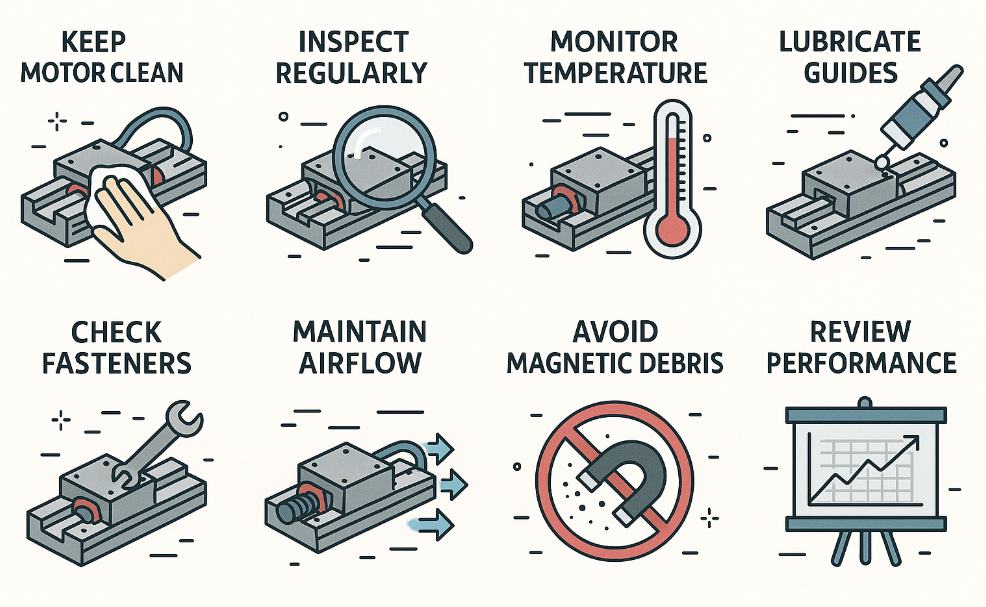

Bonus: Sample Maintenance Schedule for Ironless Linear Motor

| Task | Frequency | Tool/Notes |

|---|---|---|

| Visual inspection | Monthly | Flashlight, magnifier |

| Clean platen surface | Monthly | Isopropyl alcohol, lint-free cloth |

| Air gap measurement | Quarterly | Feeler gauge or laser sensor |

| Temperature logging | Bi-annually | External IR thermometer or sensor |

| Encoder calibration check | Annually | Calibration software + test rig |

| Cable and connector review | Quarterly | Manual inspection + continuity test |

| Bearing/guide lubrication | As needed | Based on OEM guide spec |

En

En