The Ultimate Guide to Linear Encoders and More

Table of Contents

What is a Linear Encoder?

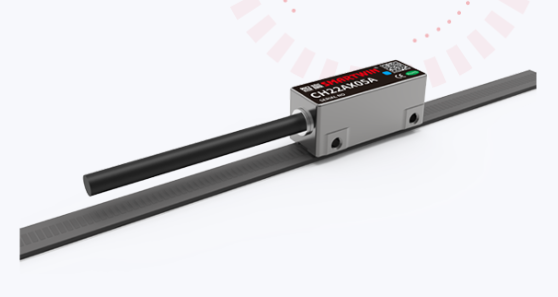

A linear encoder is a sensor, transducer, or readhead paired with a scale that encodes position. It is used to measure linear displacement — the position of a moving object with high accuracy and speed.

Linear encoders are commonly used in:

CNC machinery

Robotics

Semiconductor fabrication equipment

Precision measuring devices

Linear actuator control modules

Linear motion modules and linear slides

The main purpose of a linear encoder is to provide real-time feedback in linear motion systems such as motorized linear slides, linear actuator slides, and precision linear slides.

How Do Linear Encoders Work?

So, how does a linear encoder work? The basic principle is simple: the encoder reads position from a marked scale (using light, magnetic fields, or capacitance), and converts it into electrical signals that can be interpreted by a control system.

There are two main components:

Scale (measuring standard): A precise track with encoded information.

Readhead (sensor): Moves along the scale and converts the physical information into signals.

Let's break down how each type of linear encoder works.

How Optical Linear Encoders Work

Optical linear encoders are the most common and offer the highest resolution. Here's how optical linear encoders work:

The scale has a series of transparent and opaque lines.

A light source (LED) shines through or reflects off the scale.

A photodetector captures the light pattern.

The signal is then interpreted into digital position information.

They're ideal for clean environments like:

Medical devices

High-precision lab instruments

How Magnetic Linear Encoders Work

Magnetic linear encoders work by detecting changes in magnetic fields. Here's how magnetic linear encoders work:

The scale contains a magnetic strip with alternating poles.

A Hall-effect sensor or magnetoresistive sensor in the readhead detects pole changes.

These changes are processed to determine position.

Magnetic encoders are more robust and suitable for:

Harsh environments

Heavy-duty linear slides

Linear slide rail systems in factories

How Capacitive Linear Encoders Work

Capacitive linear encoders are less common but ideal for cost-sensitive applications. Here's how a capacitive linear encoder works:

The scale and sensor both contain electrode patterns.

As the sensor moves, the capacitance between electrodes changes.

These changes are measured to determine position.

They're used in:

Digital calipers

Entry-level CNC machines

Compact linear slides

How Does Linear Encoding Work?

You might also wonder: how does linear encoding work?

In data terms, linear encoding refers to converting analog or physical position into digital signals, ensuring accurate communication between motion hardware and control systems.

This is distinct from line encoding, which is a digital communication concept used in networking.

Applications of Linear Encoders

Linear encoders are embedded into:

Linear actuator slide assemblies in automation

Linear slide tables in robotics

Linear motion slides in pick-and-place machines

Linear modules in semiconductor manufacturing

Precision linear slides in metrology tools

Industries using linear encoders include:

CNC & metalworking

3C product assembly

Lithium battery manufacturing

Solar photovoltaic panel production

Laser cutting

LCD display manufacturing

High-end medical devices

How to Use a Linear Encoder

Wondering how to use a linear encoder? Here's a typical approach:

Mount the Scale: Affix the scale securely to the fixed part of your system (e.g., machine frame).

Install the Sensor Head: Attach it to the moving component like a slide or actuator.

Ensure Alignment: Maintain accurate gap and alignment between the scale and sensor.

Connect to Controller: Wire the output to a motion controller or PLC.

Calibrate: Set reference points and zero position.

This is typical for systems such as:

Motorized linear slides

Linear power modules

Linear actuator control modules

How to Connect Linear Encoder with PLC

To connect a linear encoder to a PLC (Programmable Logic Controller):

Determine Output Type: Most linear encoders output signals in TTL, HTL, or analog voltage.

Choose Compatible PLC Module: Ensure your PLC has high-speed counters or analog inputs.

Connect Wires: Follow the encoder’s wiring guide (usually 5V or 24V DC).

Configure PLC Program:

Use interrupt routines or high-speed counters for real-time motion tracking.

Apply scaling logic to convert counts into millimeters.

How to Test a Linear Encoder

Testing a linear encoder involves:

Visual Inspection: Look for mechanical damage or contamination on the scale.

Signal Test: Use an oscilloscope or encoder tester to check signal shape and frequency.

Functionality Test: Move the encoder and monitor output in the control system.

Resolution Test: Check for missing steps or jitter in motion profiles.

Frequent testing is essential for:

Precision linear slide systems

Heavy-duty linear slides in industrial machines

How to Make a Linear Encoder

Creating a DIY linear encoder is complex but feasible for low-resolution applications. Here's how to make a linear encoder:

Choose the Sensing Principle: Optical or magnetic are most common.

Design the Scale:

For optical: Print a grating pattern on a transparency sheet.

For magnetic: Use a magnetic tape.

Build the Readhead:

Optical: Use a photodiode and LED.

Magnetic: Use a Hall-effect sensor.

Signal Processing: Use a microcontroller to interpret the signals.

Calibrate: Map encoder counts to physical position.

This approach is great for educational projects or prototyping basic linear slide actuators.

What Does Line Encoding Mean in Contrast?

Unlike linear encoders, line encoding refers to encoding digital data for transmission over physical media (e.g., NRZ, Manchester code). It's used in:

Ethernet communication

Serial data links

While linear encoding measures position in physical motion systems, line encoding manages binary data for communication systems.

What Exactly is a Linear Optical Encoder?

A linear optical encoder is the highest-accuracy type of encoder, capable of nanometer-level precision. It is commonly used in:

Metrology tools

Semiconductor lithography systems

Laboratory automation platforms

If you’re working with compact linear slides or linear slide table systems requiring micron accuracy, a linear optical encoder is your best choice.

Choosing the Right Linear Encoder

When selecting a linear encoder, consider:

| Parameter | Recommendation |

|---|---|

| Environment | Optical for cleanroom, magnetic for harsh |

| Resolution | Optical > Capacitive > Magnetic |

| Budget | Capacitive is cheapest |

| Mounting space | Choose compact linear slides if tight |

| Load capacity | Heavy duty linear slides for large loads |

| Signal compatibility | Ensure PLC or controller can read it |

Always match your encoder to your linear motion module, linear slide rail system, or linear actuator control module for best results.

Conclusion

Whether you're working in industrial automation, CNC manufacturing, or semiconductor fabrication, understanding how linear encoders work is critical for maintaining accuracy, efficiency, and reliability.

By mastering the differences in technologies — from optical, magnetic, to capacitive — and learning how to install, test, and integrate them, you gain full control over your linear motion systems.

En

En